Introduction: Shining a Light on UV Coating

Have you ever picked up a product and marveled at its smooth, glossy finish? Chances are, you’ve encountered the magic of UV coating without even realizing it. This innovative technique is rapidly becoming the go-to choice for companies seeking to elevate their product aesthetics. In this blog post, we’ll explore the world of UV coating, its benefits, and why it’s becoming an essential tool in the designer’s arsenal.

What Exactly is UV Coating?

UV coating, short for ultraviolet coating, is a printing technique that uses ultraviolet light to cure or dry a special coating applied to printed materials. This process creates a high-gloss, durable finish that not only looks great but also protects the underlying print.

The Science Behind the Shine

The UV coating process involves these key steps:

- Application of a liquid coating to the printed surface

- Exposure to intense UV light

- Rapid curing and hardening of the coating

This quick-drying method allows for faster production times compared to traditional coating techniques, making it an efficient choice for businesses looking to streamline their processes.

The Benefits of UV Coating

1. Enhanced Visual Appeal

One of the primary reasons companies opt for UV coating is the striking visual impact it creates. The high-gloss finish adds depth and vibrancy to colors, making images pop and text appear sharper. This enhanced aesthetic can significantly improve the perceived value of a product, catching the eye of potential customers.

2. Increased Durability

UV coating doesn’t just look good; it also serves a practical purpose. The hardened layer provides excellent protection against:

- Scratches and scuffs

- Moisture damage

- Fading from sunlight exposure

This added durability ensures that products maintain their appearance for longer, even with frequent handling or exposure to challenging environments.

3. Versatility in Application

UV coating can be applied to a wide range of materials, including:

- Paper and cardboard

- Plastic

- Metal

- Wood

This versatility makes it an ideal choice for various products, from packaging and marketing materials to electronics and furniture.

UV Coating vs. Traditional Coating Methods

When compared to conventional coating techniques like lamination or varnishing, UV coating offers several advantages:

- Faster drying time

- Higher gloss levels

- More environmentally friendly (lower VOC emissions)

- Better adhesion to difficult surfaces

These benefits make UV coating an attractive option for companies looking to improve their product aesthetics while also considering efficiency and environmental impact.

Revolutionizing Product Design

The advent of UV coating has opened up new possibilities for product designers. Here’s how this technology is changing the game:

Creating Unique Textures

UV coating isn’t limited to just smooth, glossy finishes. Designers can now experiment with various textures and patterns, adding another dimension to their creations. From subtle matte finishes to bold, tactile designs, UV coating allows for a level of customization previously unattainable.

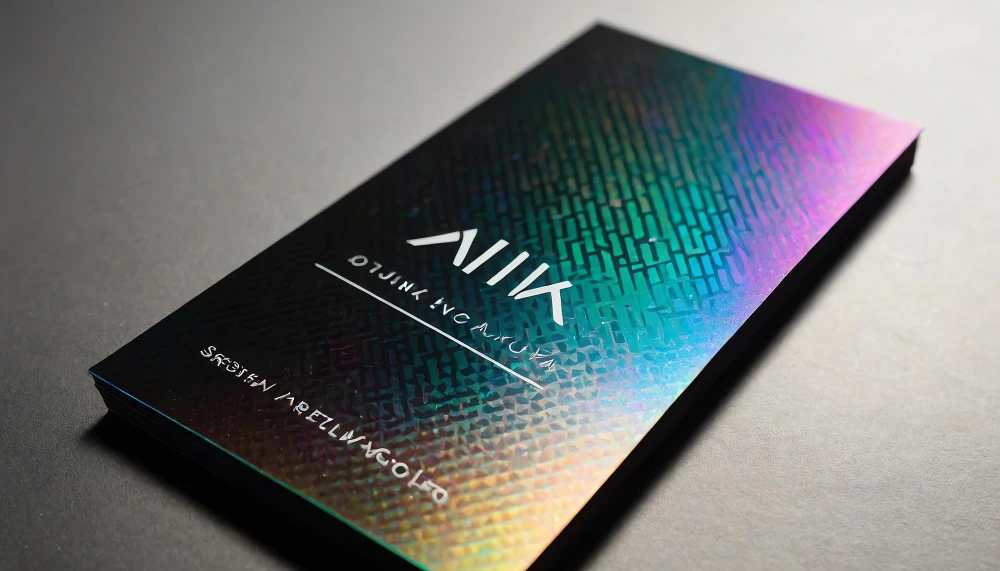

Spot UV Coating for Added Impact

One particularly exciting application of UV coating is spot UV, where the coating is applied selectively to certain areas of a design. This technique can be used to:

- Highlight specific elements of a design

- Create contrast between glossy and matte areas

- Add subtle branding elements

Spot UV coating allows designers to guide the viewer’s eye and create a more engaging visual experience.

Enhancing Brand Identity

With its ability to create eye-catching finishes, UV coating has become an essential tool for brand differentiation. Companies can use this technique to:

- Create a consistent, high-end look across product lines

- Develop unique packaging that stands out on store shelves

- Reinforce brand identity through tactile experiences

Choosing the Right UV Coating Service

For companies looking to incorporate UV coating into their product design, selecting the right service provider is crucial. Here are some factors to consider:

- Experience and expertise in UV coating techniques

- Quality of equipment and materials used

- Range of coating options available (full coverage, spot UV, textures)

- Turnaround time and production capacity

- Environmental certifications and sustainability practices

It’s also important to request samples and discuss your specific needs with potential providers to ensure they can deliver the desired results.

The Future of UV Coating

As technology continues to advance, we can expect to see even more innovative applications of UV coating in product design. Some emerging trends include:

- Integration with digital printing for more complex designs

- Development of new coating formulations for enhanced properties

- Increased use in 3D printing and additive manufacturing

These developments promise to further expand the possibilities for creating unique and visually stunning products.

Conclusion: Illuminating the Path to Better Product Design

UV coating has truly become a secret weapon for designers and companies looking to elevate their product aesthetics. Its ability to create eye-catching, durable finishes while offering versatility and efficiency makes it an invaluable tool in today’s competitive market.

As we’ve explored in this blog post, UV coating offers numerous benefits, from enhanced visual appeal to increased durability. Its applications span a wide range of industries and materials, opening up new possibilities for product design and branding.

For companies seeking to make their products stand out, investing in UV coating services can be a game-changer. By embracing this innovative technology, businesses can create products that not only look great but also leave a lasting impression on customers.

As the world of product design continues to evolve, UV coating will undoubtedly play a significant role in shaping the aesthetics of tomorrow’s products. So, why not explore how this secret weapon can revolutionize your own product designs?